Pillow Block VS Flange Block

A Pillow Block is a pedestal used to provide support for a rotating shaft. An anti-friction bearing is contained and mounted inside the pedestal. Pillow Block are also referred to as a Housed Bearing Unit, meaning they are self-contained, greased, sealed and ready for installation on the equipment.

A Pillow Block refers to any mounted bearing wherein the mounted shaft is in a parallel plane to the mounting surface, and perpendicular to the center line of the mounting holes, as contrasted with various types of Flange Blocks or flange units.

Solid VS Split Housing

Pillow Block (solid housing) differ from Plummer Block (split housing). Split type housings are usually two-piece housings where the cap and base may be detached, while solid housing may be single-piece housings. Plummer Block are bearing housings supplied without any bearings and are usually meant for higher load ratings and a separately installed bearing.

The fundamental application of both types is the same, which is to mount a bearing safely enabling its outer ring to be stationary while allowing rotation of the inner ring.

Bearing Type

Pillow block bearings can contain several types of bearings, including :

- Ball

- Roller

- Tapered

Shaft Attachement

Shaft attachment devices can be :

- Set screw,

- Eccentric lock

- Concentric lock

- Tapered adapter

Set Screw

- Easy to Install

- Lowest Purchase Price

- Clearance Fit

- Moderate Shaft Damage*

- Low to Medium Speed

*Note: this shaft attachment method can cause fretting corrosion, making removal difficult after years of operation

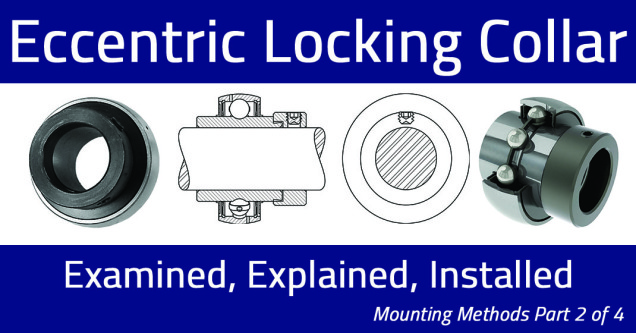

Eccentric Lock

- Easy to Install

- Relatively Low Market Price

- Uni-directional

- Minor Shaft Damage

- Low to Medium Speeds

*Note: this shaft attachment method is unidirectional and NOT intended for reversing loads. Eccentric locking collar mounted bearings contact the shaft over a larger surface area compared to setscrew mounted bearings. This can reduce shaft damage and fretting corrosion.

Concentric Lock

- Easy to Install

- Minimal Shaft Damage

- Concentric Grip to the Shaft

- Provides a More Balanced Effect Ideal for Medium to High Speeds

*Note: this mounting method is helpful to minimize vibration.

Tapered Adapter

Tapered adapter assemblies consist of a tapered adapter sleeve, a lock washer and a lock nut. As the adapter is tightened using a spanner wrench, the adapter is drawn through the bearing and tightened to the shaft. Because the contact of the bearing is evenly distributed around the shaft, it provides the most concentric/ideal fit.

How to Video !

Aucun commentaire:

Enregistrer un commentaire